We provide flexible and dynamic warehouse systems for your specific needs.

Reap the benefits of our efficient, high-performance and tailor-made warehouse systems!

Modern warehouse systems must be able to locate and supply required items quickly and accurately. These requirements are met by our sophisticated automated warehouse systems combined with smart warehouse management software. Our solutions are energy-efficient, durable and customized for all industries and areas of application. As we’re experts on automated warehouse systems, we provide you with a one-to-one consulting service, tailor-made concept design, professional construction and precise manufacturing, as well as expert assembly and commissioning. At MFI, we’re committed to making sure your warehouse management system is future-proof.

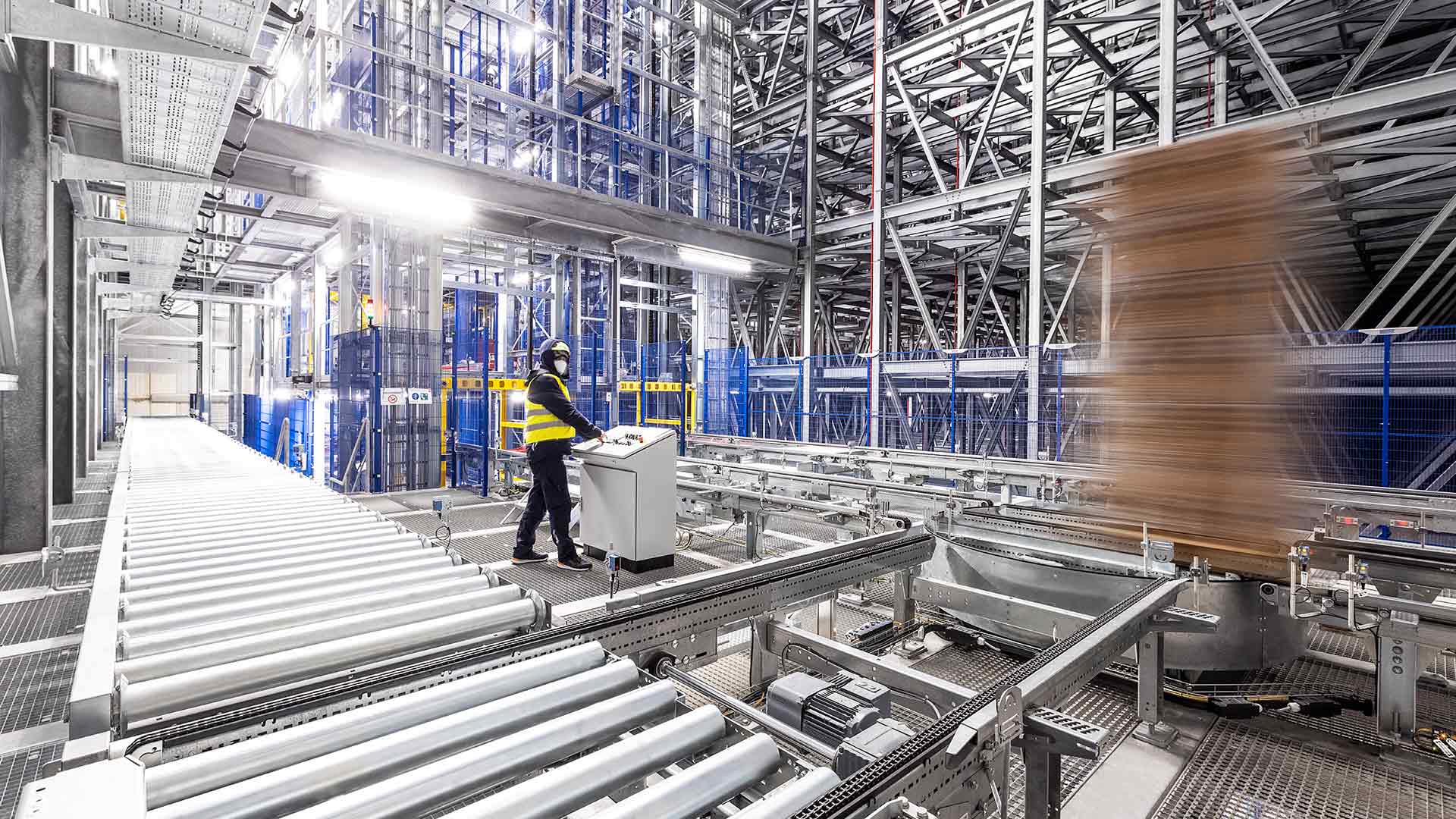

Make the best use of limited floor space with our automated high-bay warehouse. It doesn’t matter whether your products are stored on pallets or trays, in cartons or boxes, as stacks or rolls: we are on-hand to offer you the right warehouse solution for your needs. Our product range includes single-deep, double-deep or multiple-deep storage types, depending on how many items you have, and required performance of your automated high-bay warehouse. A channel storage system is the most efficient solution for a small range of large-volume products.

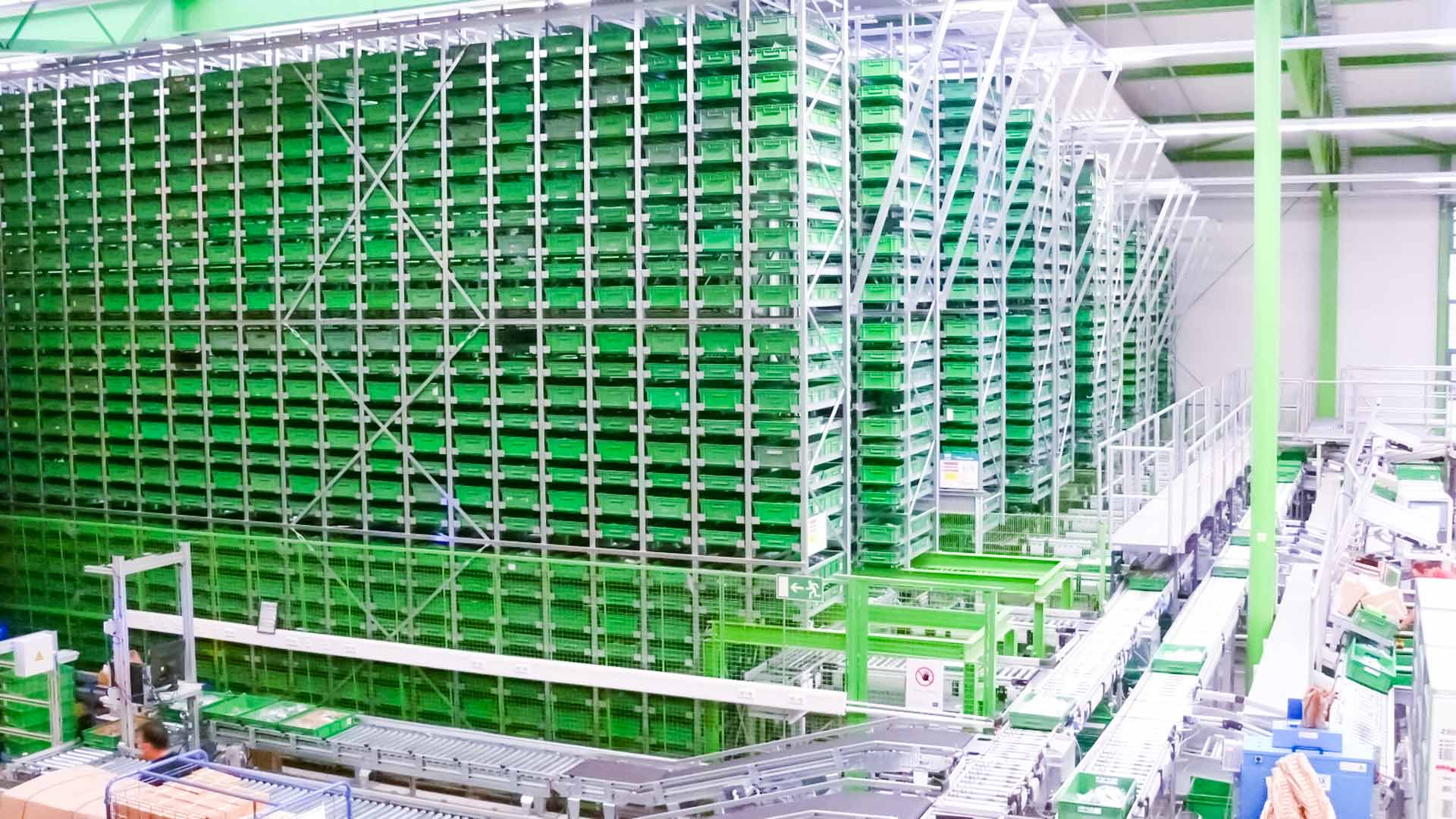

Using our automated small parts warehouse (AKL) means you will have your entire stock of small parts fully under control. Our software’s control functions allow you to store and retrieve even the smallest parts in cartons, trays or other containers efficiently, reliably and in a way that saves a huge amount of space. High speed, absolute precision and exceptional reliability – this is what makes the difference in your automated small parts warehouse. You will have all three of these amazing benefits and more with our shelving system combined with our high-speed storage and retrieval units, our intelligent conveyor technology, and our smart warehouse software.

When automated small parts warehouses reach their limits, this is where dynamic warehouse systems come in, most notably in the form of a shuttle warehouse. They utilise every nook and cranny of the storage space available as they are not bound to a uniform shelf height. Our offer includes captive, roaming and 3D shuttle warehouses. We integrate the required pre-zones and lift systems into your rail system so that you can reach all of your stored parts quickly and easily by using shuttle vehicles. A warehouse with a shuttle system is an effective solution to improve the efficiency of your horizontal and vertical transport.

Dynamic picking systems guarantee high-quality performance, which means you save time. This is ensured by our NEO storage and retrieval unit - made of 100% stainless steel, which has been specially developed for the food industry - or it’s available in steel/aluminium for other sectors if needed. NEO is the best possible solution for quick replenishment, allowing smaller containers to be distributed at breakneck speed. Our newly developed and patented FKS, a flexible picking storage system, is another fantastic innovation for picking a wide range of stored items. Find more about FKS here.

In-house material flows are the most crucial elements in any production chain and require efficient temporary material storage. TARO, our modular storage system concept is an intelligent and flexible solution for buffering boxes, baskets and trays up to a 500kg payload. Powerful TARO L or XL shuttle vehicles are the beating heart of the buffer. This system has a high storage density and it optimises process performance, allowing you to save money and maximize space. Learn more about TARO here.

TARO das modulare Lagersystem Konzept. Dieser intelligente und flexible Puffer mit variablen Shuttlesystemen eignet sich perfekt für Kisten, Körbe, Dielen, Tablare bis zu 500kg Traglast. Herz des Puffers sind starke TARO L oder XL Shuttlefahrzeuge. Dieses System kann leistungsoptimiert, kosten- und platzsparend eingesetzt werden und verfügt über eine hohe Lagerdichte. TARO Lagersystem ist flexibel und skalierbar, da es sich im Laufe der Zeit verändern oder erweitern lässt, um sich an neue Anforderungen des Unternehmens anzupassen.

Edit this rich-text to provide the visitor with all appropriate information. You might add images, calls-to-action, horizontal rules, videos, quotes, etc. All this and more can be done through the text editor.

Our modern warehouse technology improves the efficiency of your production processes, reduces the need for space and uses less energy.

We provide you with an entire warehouse system from a single source: from design and production, to installation and commissioning.

SCIO Automation Intrasolutions GmbH

Headquarter

Donau-Gewerbepark 30

94486 Osterhofen

Phone: +49 9932 9504 0

Mail: wis.info@scio-automation.com