Comply with hygienic requirements and increase production throughputs by using our customised automation solutions for the food industry.

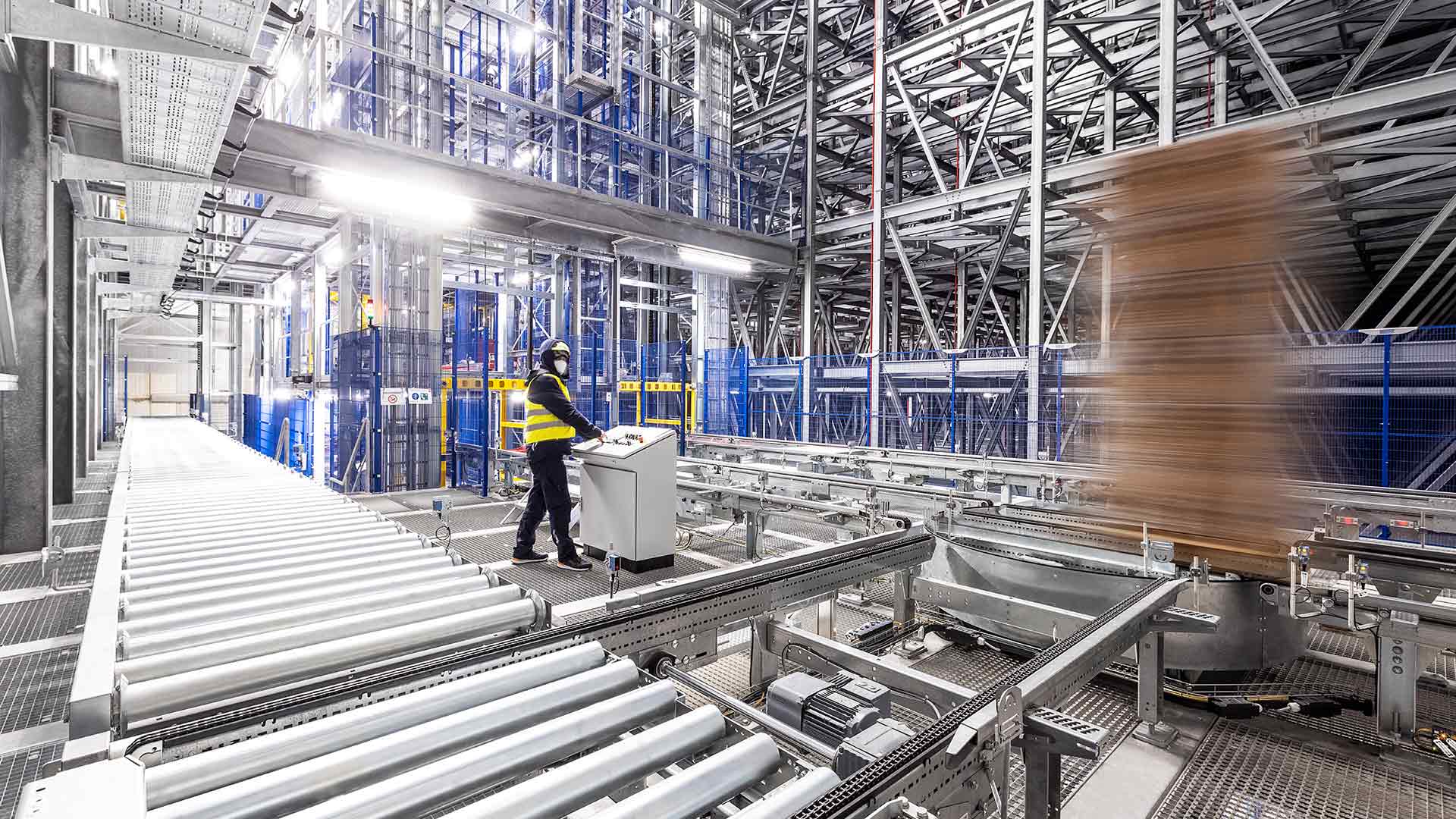

Hygiene is crucially important in food industry intralogistics. Speed and flexibility can also make the difference between success and failure. You can improve the efficiency of your food production systems by using our automated warehouse and conveyor technology. As a manufacturer of stainless steel intralogistics for the food industry, we are able to simplify your complex processes. We also keep an eye on hygiene at all times, that goes without saying. That’s why all of our components, from our conveyor technology and storage and retrieval machines to stackers and destackers, are made of hygienic stainless steel. We will also be happy to manufacture and integrate your new intralogistics systems in steel, if required.

We design the best conveyor systems for your specific needs using our in-depth expertise.

Learn more →

Innovative, fully bespoke solutions with high-quality systems for transport and storage.

Learn more →

Our robotic systems are tailored to your specific requirements, they are unique and extremely accurate.

Learn more →

An intelligent IT solution to help you tackle the intralogistics challenges in the food industry.

Learn more →

Service that fits around you, which includes retrofitting for your systems and machines. Learn more about our no-hassle package.

Learn more →

An intelligent and flexible buffer with variable shuttle systems for basket, box, and tray logistics.

Learn more →

A modern storage and retrieval unit with low approach dimensions and exceptional performance data.

Learn more →

The best solution on the market for flexibly and automatically stacking or destacking trays and baskets.

Learn more →

The world’s first Multiflex warehouse for the deep-freeze sector that was designed and built in Germany has now been put into operation. The whole project was completed within a tight timeframe of only 13 months. Find out more about this MFI project in the MM Logistik article.

To the article →

Hygienic design is an important factor when it comes to investing in equipment for bakeries. But how do clients approach it? Find out more in the interview with Jan Schumacher.

To the interview →

Remote commissioning has become increasingly prevalent in recent months. Read about our experience in an interview with trade journal "Technik + Einkauf".

Read the article →We are always looking to create the best solutions that we can, using state-of-the-art technology to make day-to-day business operations more convenient for you. Innovation drives us!

We provide you with our expertise at any stage along the entire value chain: from design to engineering, production, commissioning and after-sales service.

Our experts try to see things from your perspective, as this helps us to create efficient solutions to meet your requirements.

We like to take a partnership-based approach while working with you. This is how we build trust, ensuring that our working relationship remains strong moving forward.

Our many years of experience allows us to implement your projects by leveraging our extensive expertise and broad portfolio of MFI products.

Case Bäckereibetrieb

SCIO Automation Intrasolutions GmbH

Headquarter

Donau-Gewerbepark 30

94486 Osterhofen

Phone: +49 9932 9504 0

Mail: wis.info@scio-automation.com