Keep tradition alive whilst improving efficiency by using our customised, automated solutions for bakeries.

We combine the traditional art of baking with advanced intralogistics. Our fully automated conveyor technology transports your baked goods from A to B. It doesn’t matter whether this is in production, or in your basket warehouse – your product will be handled in a hygienic way, anytime, anywhere, guaranteed. All our intralogistics components are made of stainless steel and are easy to clean. As a manufacturer of intralogistics solutions for bakeries, we help you to automate transport and production processes in your bakery. Our ultimate goal is to improve the efficiency of your production line.

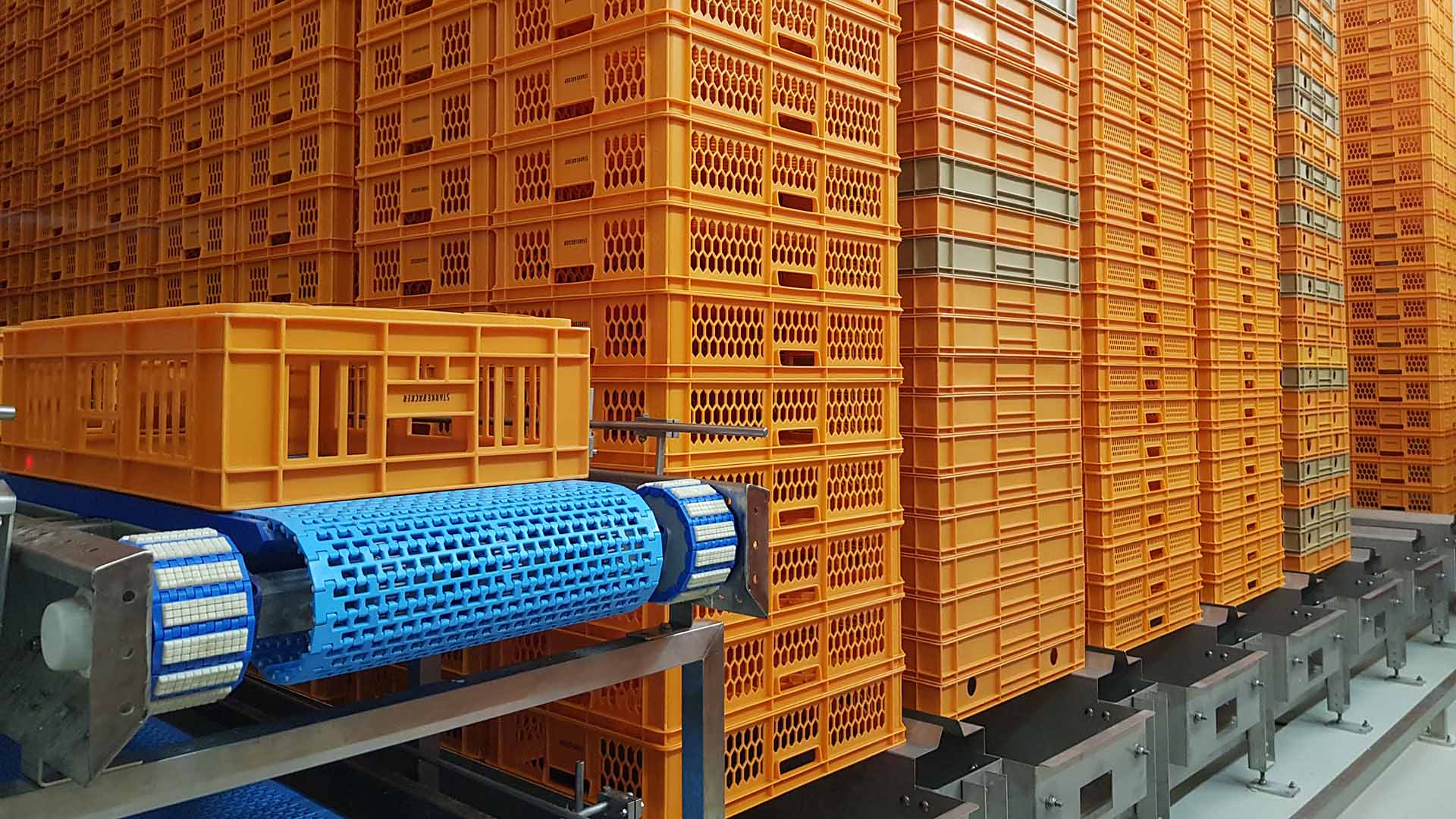

Stainless steel conveyor technology, that have been specifically developed for plastic trays or baskets in bakeries.

Learn more →

Innovative, fully bespoke solutions with high-quality systems for transport and storage.

Learn more →

Our robotic systems are tailored to your specific requirements, they are unique and extremely accurate.

An intelligent IT solution to help you tackle the intralogistics challenges in your bakery.

Learn more →

Service that fits around you, which includes retrofitting for your systems and machines. Learn more about our no-hassle package.

Learn more →

Patented innovation for a fully automated and gentle bread packaging process.

Learn more →

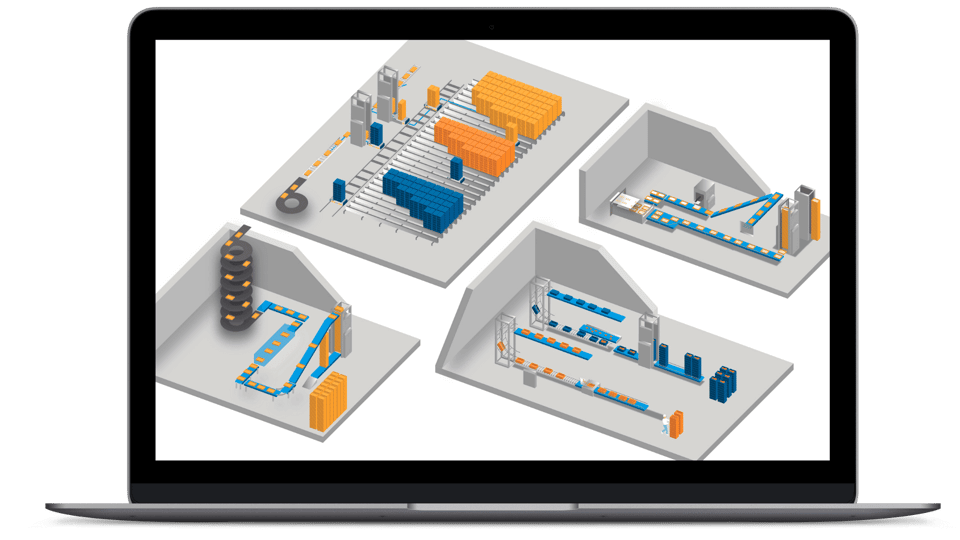

An intelligent and flexible buffer with variable shuttle systems for basket, box, and tray logistics.

The best solution on the market for flexibly and automatically stacking or destacking trays and baskets.

Learn more →

Specifically developed for the baking industry: a mobile paper magazine for automatically inserting papers or non-wovens into trays or baskets.

Pre-picking different shapes and sizes of bread loaves into shipping baskets can be automated by using Octa, which also ensures that your baked goods are properly quality controlled.

Learn more →

Starke Bäcker has automated its basket logistics system with a compact and flexible system engineered by MFI. This has enabled the Schwanewede bakery to save on floor space and reduce labour costs.

To the report →

After everyone experienced the disappointment of Südback and other trade fairs being cancelled 2 years running, we would now like to invite you to visit us at our virtual MFI stand at the Bäckerwelt trade fair in 2022.

Go to the virtual fair →We are always looking to create the best solutions that we can, using state-of-the-art technology to make day-to-day business operations more convenient for you. Innovation drives us!

We provide you with our expertise at any stage along the entire value chain: from design to engineering, production, commissioning and after-sales service.

Our experts try to see things from your perspective, as this helps us to create efficient solutions to meet your requirements.

We like to take a partnership-based approach while working with you. This is how we build trust, ensuring that our working relationship remains strong moving forward.

Our many years of experience allows us to implement your projects by leveraging our extensive expertise and broad portfolio of MFI products.

Case study of a bakery business

Bakery Intralogistics Production hall

Bakery Wash Hall

Bakery Intralogistics Wash hall

Bakery Intralogistics Bun chute

Bakery Basket Store

Paper inserter pastry

Spirals with C-turn

Stapler für Brötchen und Feingebäck

Bread packing station

Hero, Universalstapler

Conveyor technology, basket storage

Octa packaging robot and Hero universal stacker

SCIO Automation Intrasolutions GmbH

Headquarter

Donau-Gewerbepark 30

94486 Osterhofen

Phone: +49 9932 9504 0

Mail: wis.info@scio-automation.com